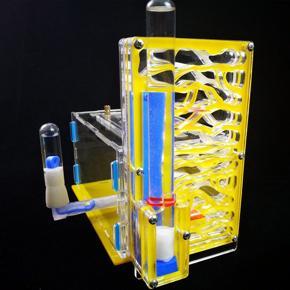

DASI 12V/24V/110V-220V STC-1000 Digital LCD Temperature Controller Sensor for Aquarium hatching seafood machine electronic Thermostat Control

(0

Reviews)

Price

৳916.00 - ৳1,007.60

Refund

Not Applicable

Share

Top Selling Products

Reviews & Ratings

0

out of 5.0

(0

Reviews)

There have been no reviews for this product yet.

Material: ABS

Color: Grey.

Specifications:

Panel Size: Length * width/75*34mm.

Machine Size: Length * width * high/85*75*34mm.

Mounting Size: Length * width/71*29mm.

Measurement and control temperature range: -50℃~+99℃.

Accuracy: ±1℃.

Resolution: 0.1.

Power: Less than 3 W.

Sensor: NTC sensor (line length 1 m).

Power supply: 110-220VAC±10%, 50/60Hz (or DC12V/DC24V).

Relay output Capacity:

Heating: 10A/240VAC, Refrigeration: 10A/240VAC.

Front panel protection level: IP65.

Scope of application: Seafood machine, aquarium, chiller, etc., as well as the need for refrigeration, heating automatic switching equipment.

Features:

1, refrigeration, heating mode automatic conversion;

2, back differential temperature control mode;

3, temperature correction;

4, refrigeration control output delay protection;

5, excessive process and sensor fault alarm.

Code Description:

P0-Refrigeration, Heating mode:

High temperature start for refrigeration mode please set to C; Low temperature start for heating mode please set to H.

P1-Back Difference settings:

Under Heating mode (H): The measured value ≤ set value-the start output is heated to the set value stop when the return difference.

Under Refrigeration mode (C): The measured value ≥ set value + The return difference when the startup output is cooled to the set value stop.

P2-Highest Setting Range:

The highest value does not exceed this value when setting the temperature.

P3-Minimum Setting Range:

The minimum value is not less than this value when setting the temperature.

P4-Temperature Correction:

When measuring temperature and standard temperature deviation, you can use this function correction, the corrected temperature = the pre-correction temperature + calibration value.

P5-Delay Start time unit: minutes.

When controlling the refrigeration of the compressor equipment, the delay time can be set according to the need, when the controller output the device will not start immediately, need to run after the set delay time to start.

P6-High Temperature alarm:

When the measured value is greater than this value, the screen displays---and drops the sound alarm while forcing the output to be disconnected.

P7-Data Lock function:

Turn on the data lock, you can keep the current settings from being changed, at this time the setting temperature and function are not valid, if you want to modify, you need to turn off the data lock function.

P8-Restore factory settings:

Press and hold set to switch to P8, press once setting to ON, press Rst to restore factory settings, or you can press down the +-key do not release the machine self-test and restore factory settings.

Instructions for use:

1. Connect the power supply according to the parameters and circuit diagram, and replace the refrigeration or heating equipment on the output side.

2, according to the need to enter the internal settings to choose heating (into the P0 selection H) or refrigeration (into the P0 selection C) mode.

3, set the temperature method: Press the Set screen flashing, press the upper and lower settings of the desired temperature, according to the Rst confirmation return.

4, the panel's out indicator: flashing indicates refrigeration or heating start delay, constant light represents the output.

5, digital tube display meaning: Display lll for the sensor open, display HHH to exceed the measuring range of the thermostat will force power outage, display---for high temperature alarm.

Packaging includes:

1x thermostat.

1x probe line.

1x instructions.

Related products

Top Selling Products

Support